To track time and productivity in manufacturing and mining operations, businesses must adopt a robust time and attendance software, monitor performance and enhance on-site productivity.

In the high-stakes environment of mining and manufacturing, the demand for 24/7 operations is a constant reality. These industries often operate around the clock to meet production goals and maintain competitive advantages. However, tracking time and operational productivity is crucial for optimising efficiency, reducing costs, and enhancing overall performance. Effective time tracking and productivity monitoring help manage resources, improve workflows, and ensure regulatory compliance.

This comprehensive guide explores effective strategies and technologies for tracking time and productivity, supported by research to help businesses within the manufacturing and mining sectors across Africa to make informed decisions.

The Unavoidable Need for 24/7 Operations and the Role of Time Tracking

Mining and manufacturing industries are driven by the need for uninterrupted operations. The continuous nature of these industries requires a well-coordinated approach to managing shifts and preventing worker fatigue. Time tracking software is essential in this context, as it facilitates efficient shift rotations and ensures that workers are not overextended.

With advanced time tracking systems, companies can automate shift scheduling, reducing administrative overhead and minimising the risk of scheduling errors. A time tracking software, such as SeamlessHR time and attendance software helps in tracking hours worked, breaks taken, and the time each employee spends on specific tasks.

How To Track Time and Productivity In Manufacturing and Mining Operations

Effective time and productivity tracking helps manage resources, streamline processes, and enhance overall productivity. Here’s how to efficiently monitor time and productivity in the manufacturing and mining industries:

- Implement a time and attendance software to track time and productivity.

Implementing advanced time tracking systems is essential in tracking time and productivity in manufacturing and mining operations. Technologies such as biometric time clocks, RFID and mobile apps provide precise data and minimise errors. Biometric systems use fingerprint ID recognition or facial recognition for accurate identification, while RFID badges offer a secure, touchless clock-in method.

Efficient shift management is also crucial. Automated tools for shift scheduling help handle complex needs, track changes, and monitor attendance of on-site workers. The International Journal of Production Economics (2022) reports that optimised scheduling can increase productivity by 10-15% by ensuring effective use of labour resources. Features like automatic shift swaps and real-time updates improve workforce management and reduce scheduling conflicts.

Also, integrating time tracking systems with payroll software further streamlines the compensation process. Companies that integrate these systems experience a 30% reduction in payroll errors and a 20% decrease in processing time, according to the Workforce Institute (2022). This integration ensures accurate wage calculations, simplifies compliance with labour regulations, and reduces administrative burdens, making the entire process more efficient.

SeamlessHR time and attendance software in Nigeria, Kenya, Ghana, South Africa, Tanzania, Uganda and other African countries eases the flow.

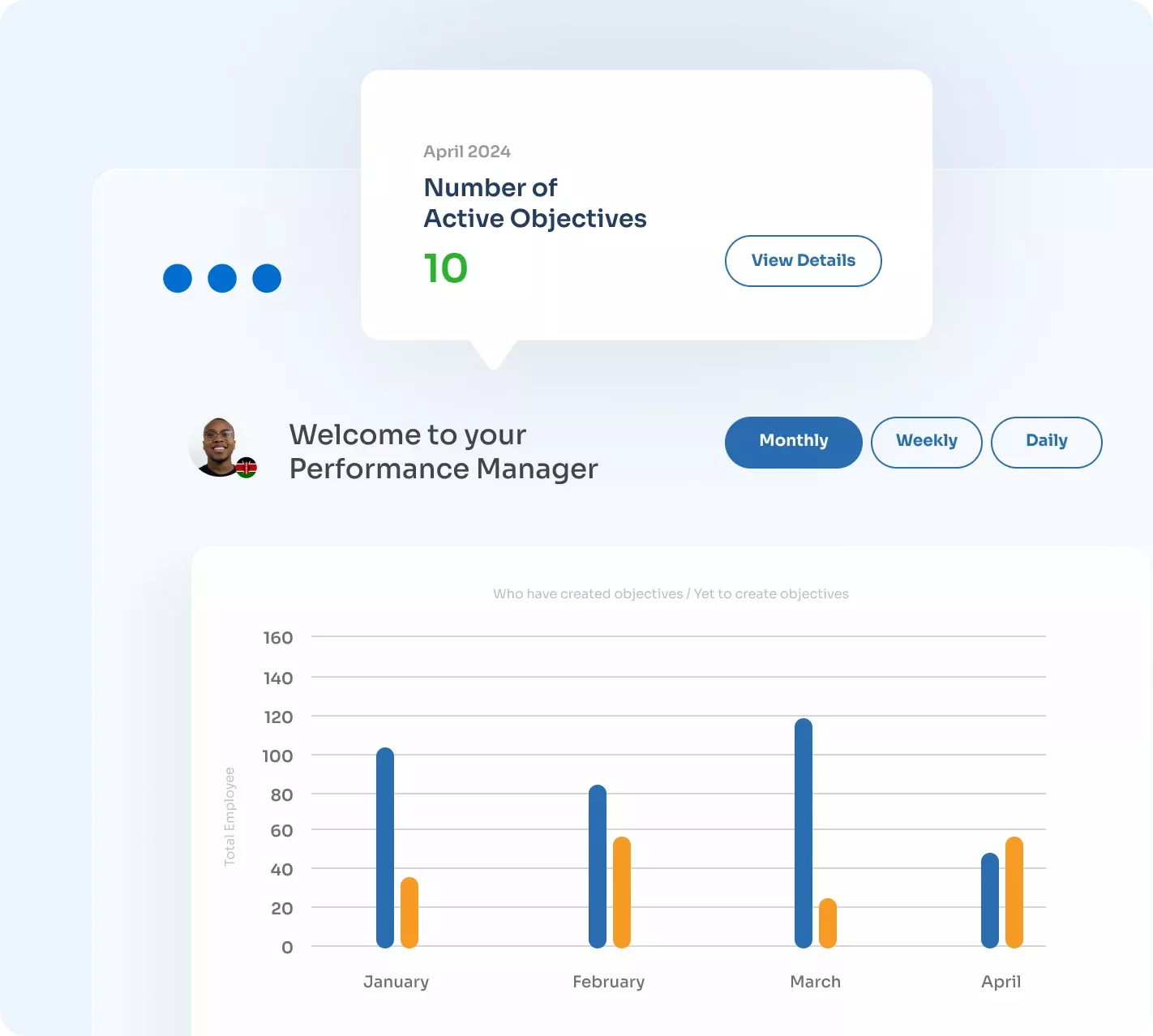

- Track productivity with SeamlessHR performance management software

Tracking operational productivity effectively involves leveraging key performance indicators (KPIs), data analytics, and real-time dashboards. Establishing KPIs such as production output, equipment utilisation rates, and downtime is crucial for gaining insights into performance.

According to McKinsey & Company (2021), companies using real-time performance metrics can see up to a 15% improvement in operational efficiency. Productivity monitoring tools that track these metrics enable timely adjustments and data-driven decision-making. Data analytics further enhances productivity by analysing historical data to identify trends, inefficiencies, and areas for improvement. A study in the Journal of Operations Management (2020) shows that data-driven decisions can boost productivity by up to 25%. Advanced analytics tools provide actionable insights from large datasets, allowing businesses to optimise processes and increase overall efficiency.

Importantly, real-time dashboards offer a visual overview of key productivity metrics, helping managers make quick, informed decisions. Harvard Business Review (2022) highlights that real-time data visualisation improves decision-making speed and accuracy by 30%. Dashboards that display metrics such as production rates, equipment status, and employee performance enable immediate adjustments and proactive management of operations.

- Monitor equipment and process efficiency

Effectively monitoring equipment and processes is crucial for maintaining operational efficiency. Utilising IoT sensors and tracking devices provides real-time data on equipment status and usage, helping to reduce downtime by up to 50% and maintenance costs by 30% (Deloitte, 2023). This approach allows for early detection of issues, preventing costly breakdowns and ensuring continuous operation. Additionally, analysing workflows and task durations with time tracking software can highlight inefficiencies, leading to a potential 20% increase in production efficiency by streamlining processes (Journal of Manufacturing Science & Engineering, 2021).

Adopting a proactive maintenance strategy further enhances operational efficiency. By leveraging equipment data for preventive and predictive maintenance, companies can reduce operational downtime by up to 40% (International Journal of Advanced Manufacturing Technology, 2022). Scheduling regular maintenance and addressing issues before they escalate ensures smooth, uninterrupted operations, minimising disruptions and improving overall performance.

- Enhance workers’ productivity on-site.

Enhancing worker productivity involves several key factors. Continuous training and development are crucial, as they significantly boost productivity and performance. The American Society for Training and Development (2022) found that organisations investing in employee training experience a 24% higher profit margin and a 218% higher income per employee. Ongoing training ensures employees are adept at using advanced technologies and best practices.

Workplace ergonomics also play a vital role in improving productivity. Research shows that well-designed workstations and equipment can reduce physical strain and improve productivity. Additionally, creating a positive work environment that motivates and engages employees is essential. Gallup (2022) highlights that highly engaged employees are 21% more productive than their disengaged peers. Recognising achievements, involving employees in decisions, and offering career growth opportunities can further enhance productivity and morale.

Conclusion

Tracking time and productivity in manufacturing and mining operations is essential for achieving optimal performance and maintaining competitiveness. By adopting the strategies highlighted above, companies in Africa can enhance their operations and achieve better results. Adopt a time and attendance management software that effectively helps you track both time and money. Click here for a quick demo of SeamlessHR time and attendance software.